product core function is meterial curshing, conveying, mixing, dispersing, homogenizing, emulsifying, refining, it is widely used in food, pharmaceutical, commodity chemicals, industry of fine chemicals, petrochemical, papermaking chemicals, pesticides, chemical fertilizers, plastic, rubber, paint,coating meterial and so on.

application area:

The machine is used in the decomposition, dissolution, dispersion, shearing and emulsification processes of petroleum, chemical,commodity chemical, textile, food and other industrial sectors. The excellent multifunction features greatly improve mixing efficiency compared with pure mixing principle. Extensive versatility and flexibility.

operational principle:

high speed absorbed the meterial into the bottom of container, subject a strong mixing effect, meterial is through out from the stator hole after through the precisely matched stator and rotor clearance.

the new material is sucked into the center of the rotor while It subject the severe mechanical and hydraulic shear forces, the particles are torn and crushed, and then ejected material changes direction on the wall of the container, thus completing a cycle.

Performance characteristics:

- The machine is suitable for liquid-liquid, liquid-solid mixing.

- The machine has two kinds of structure, one kind of blade structure which is suit for heavy weight and easy settling material, Another kind is claw type structure which is suitable for light specific gravity suspended solids

3. Each structure has two types, one is suitable for working under atmospheric pressure, small type can carry moving lift frame, the other is suitable for situations where there is pressure and requires sealing or vacuum pumping.

Round hole stator head: suitable for crushing of mixed large particles, the circular opening in this head provides the best cycle of all stators, achieving the most perfect circulation of higher viscosity fluids

Long hole stator head: long hole provides the largest area for surface shear. It is suitable for the rapid comminution of medium solid particles and the mixing of medium viscosity liquid. The good circulation and high shear capacity indicate that this kind of head can be used in emulsification and homogenization.

Combined stator head: the combined stator mesh screen with holes provides the greatest shear effect. Strict emulsification requirements or fine powder suspension can be effectively completed by the combined stator head, which is suitable for mixing low viscosity liquids, as its shear rate is the largest, it is suitable for the preparation of emulsion and the process of crushing and dissolution small particles in liquid.

Claw structure: multi-layer dual occlusal shear, bi-directional suction

|

Technical parameters:

ADRHJ-100 Serial

|

|

100

Type

|

101

|

103

|

105

|

110

|

115

|

125

|

130

|

150

|

|

Power (kW)

|

1.1

|

2.2

|

4

|

7.5

|

11

|

18.5

|

22

|

37

|

|

Speed (rpm)

|

2900

|

2900

|

2900

|

2900

|

2900

|

2900

|

1470

|

1470

|

|

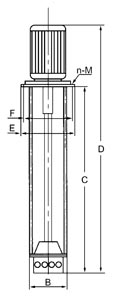

B

|

120

|

135

|

190

|

200

|

230

|

230

|

280

|

405

|

|

C

|

617

|

650

|

852

|

1130

|

1200

|

1276

|

1465

|

1650

|

|

D

|

880

|

1100

|

1220

|

1550

|

1710

|

1850

|

2100

|

2450

|

|

E

|

240

|

250

|

300

|

360

|

360

|

420

|

420

|

630

|

|

F

|

220

|

225

|

275

|

330

|

330

|

385

|

385

|

590

|

|

n-M

|

4-M10

|

4-M12

|

4-M12

|

4-M16

|

4-M16

|

4-M20

|

8-M20

|

8-M24

|

|

Proce

ssing (L)

|

15-100

|

50-150

|

50-200

|

90-1000

|

120-1200

|

150-2000

|

200-3000

|

1000-6000

|

Attentation: * flow range in form is the measured data when the medium is "water".

*The data are subject to change without prior notice, and the correct parameters are subject to the provision of physical objects

|

|

| |

|

|

ADRHJ-200 Serial

|

200type

|

201

|

203

|

205

|

210

|

115

|

225

|

230

|

250

|

|

Power kW

|

1.1

|

2.2

|

4

|

7.5

|

11

|

18.5

|

22

|

37

|

|

Speed rpm

|

2900

|

2900

|

2900

|

2900

|

2900

|

2900

|

1470

|

1470

|

|

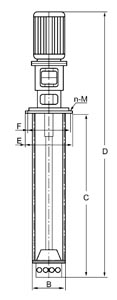

B

|

120

|

135

|

155

|

172

|

230

|

230

|

280

|

405

|

|

C

|

590

|

650

|

700

|

1070

|

1200

|

1392

|

1496

|

1750

|

|

D

|

1124

|

1330

|

1420

|

1800

|

2180

|

2410

|

2578

|

3030

|

|

E

|

280

|

250

|

280

|

350

|

360

|

420

|

420

|

460

|

|

F

|

250

|

225

|

250

|

310

|

330

|

380

|

380

|

420

|

|

n-M

|

6-M16

|

4-M12

|

6-M16

|

8-M20

|

4-M16

|

8-M20

|

8-M20

|

8-M24

|

|

Processing (L)

|

15-100

|

50-150

|

50-200

|

90-1000

|

120-1200

|

150-2000

|

200-3000

|

1000-6000

|

Attentation: * flow range in form is the measured data when the medium is "water".

*The data are subject to change without prior notice, and the correct parameters are subject to the provision of physical objects

|

|