- Summary:

Star feeding machine (closed fan machine, rotary valve, rotary discharger), it has advanced unloading, mechanized and automatic control system continuous uniform ingredient, conveying, unloading equipment. The whole machine has the characteristics of small volume, light weight, strong production capacity and convenient maintenance and operation. The machine is widely used in environmental protection, metallurgy, chemical industry, electric power, cement, grain medicine and other industries. It is an ideal equipment for the control of conveying flakes, fly ash, cement, raw clinker, grain type PET chips, plastic particles and other materials.

- Principle:

The motor drives the spindle and the impeller through the reducer, and the material enters the impeller trough through the feeding entrance through the upper material silo, the rotating impeller brings the material to the outlet and feed it out evenly. It can using stepless speed regulation machine, frequency conversion motor speed regulation and electromagnetic speed reducer to meet the requirements of different working conditions.

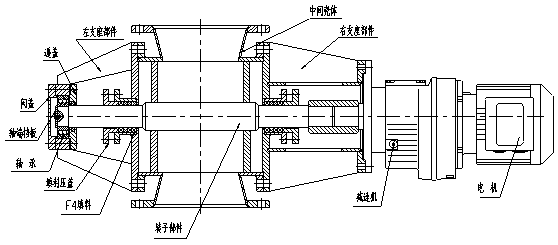

- Type A structure: cantilevel of decelerating motor:

The machine is mainly composed of motor, reducer, spindle, shell, left and right support, rotor parts, bearing and other components.

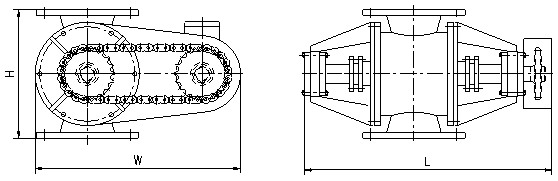

- Type B structure: sprocket chain drive:

The machine is mainly composed of motor, reducer, spindle, shell, left and right support, rotor parts, bearing, chain and other component, Three phase 4 pole vertical motor, reducer using cycloidal needle wheel reducer, gear reducer, worm gear reducer and stepless speed reducer.

The rotor component consists of eight grooved rotors composed of the spindle and its upper eight blades. the material can be moved from the feed entrance to the discharge entrance when the rotor rotates, it is filled with eight slots. Left and right support: the left and right bearings are used to support the spindle, so that the spindle is in a horizontal state to ensure smooth operation.

- Star feeding machine technical parameter:

|

Model

|

Processing

(m3/h)

|

Spindle speed

|

Power

(KW)

|

DN

|

D

|

D1

|

H

|

n-φd

|

L

|

W

|

|

Type A

|

Type B

|

Type B

|

|

ADWF-1

|

0.5

|

24r/min

|

0.55

|

80

|

Φ185

|

Φ150

|

300

|

4-φ18

|

830

|

/

|

/

|

|

ADWF -2

|

1

|

0.55

|

100

|

Φ205

|

Φ170

|

300

|

4-φ18

|

830

|

/

|

/

|

|

ADWF -3

|

3

|

0.75

|

125

|

Φ235

|

Φ200

|

360

|

8-φ18

|

950

|

680

|

580

|

|

ADWF -4

|

5

|

0.75

|

150

|

Φ260

|

Φ225

|

380

|

8-φ18

|

1000

|

700

|

600

|

|

ADWF -5

|

7

|

24r/min

|

1.1

|

200

|

Φ315

|

Φ280

|

420

|

8-φ18

|

1100

|

780

|

620

|

|

ADWF -6

|

14

|

1.5

|

250

|

Φ370

|

Φ335

|

450

|

12-φ18

|

1150

|

800

|

680

|

|

ADWF -7

|

22

|

2.2

|

300

|

Φ435

|

Φ395

|

500

|

12-φ23

|

1200

|

950

|

800

|

|

ADWF -8

|

35

|

2.2

|

350

|

Φ485

|

Φ445

|

580

|

12-φ23

|

1400

|

1000

|

860

|

|

ADWF -9

|

55

|

33r/min

|

3

|

400

|

Φ535

|

Φ495

|

600

|

16-φ23

|

1450

|

1050

|

900

|

|

ADWF-10

|

100

|

4

|

500

|

Φ640

|

Φ600

|

740

|

16-φ23

|

1550

|

1350

|

1150

|

Attentation: 1. The processing capacity and motor power listed are designed according to the conveying particles, and other materials can be redesigned according to the requirements of the users.

2. The inside and outside diameter is designed according to JB/T81-94 pressure grade PN0.25MPa, and can be redesigned according to the requirements of users.

3. Special materials, special working conditions, can call communication, the factory can design and manufacture according to special requirements.

- Characteristics of star-shaped feeder for powder and particle:

- Bite-proof design at feeding entrance to avoid particle shearing in operation. Reduce equipment vibration and fault risk, reduce particle breakage, improve transport quality.

- Internal polishing process to avoid the adhesion of powder materials, and phenomenon of no feeding in the bridge.

- Strengthen bearing support Design, improve rotor fit Precision

- The self-lubricating PTFE packing seal is adopted at the rotary shaft, which reduces the wear of the packing and reduces the dust leakage.

5. Compact structure, small space.

- Features of high concentration star feeding machine for powder and particle (suitable for high pressure air conveyance and high airtight requirement).

- Suitable for inside and outsidet pressure range: 1 kg / cm 2 system pressure or pressure difference

- The special design of shell inside and outside section can effectively prevent the extruding and crushing of granular materials and prolong the life of equipment, it can safely start and improve the conveying quality even if the upper reaches are filled with materials.

- The entrance and exit are designed with large opening and high inclination angle to improve the flow of powder.

- High strength shell and axis, can bear high pressure and stable operation.

- Low clearance between casing and wheel blade to improve transportation efficiency.

- The axial center adopts packing material seal to reduce dust leakage and gas leakage.

7. Specially designed exhaust outside of shell to increase exhaust effect and improve filling efficiency.

- Characteristics of high temperature resistance star feeding machine.

- The closed fan with SUS321 material can transport materials with temperature less than 700 ℃.

- After welding the equipment shell and rotor, through remove stress processing to prevent the heat deformation when the equipment conveys the high temperature material, so as to ensure that the rotor and the shell do not get stuck and the equipment runs smoothly.

- The rotary shaft adopts hollow structure, with a specially designed cooling unit built in, and a rotary joint is arranged at the end of the shaft to cooling the water, a large amount of heat can be taken out through the heat of cooling water exchange of the cooling water so that the equipment can work effectively for a long time.

- The high temperature bearing filling the high temperature oil to ensure that the rotor is flexible and flexible, and the structure is externally effective to prevent the dust from invading the bearing and increasing the use range of the equipment to the higher temperature.

- High temperature resistant graphite disk root seal is adopted at rotation shaft to reduce dust leakage.

- Using chain wheel chain drive, motor reducer is separated from the equipment shell and block the direct heat conduction, so effectively protect the transmission machinery.

- Strengthen bearing support Design, improve rotor fit Precision.

8. The whole structure is sturdy and compact, exquisite and beautiful.

- Preparation for installation and operation:

- The upper and lower flange fixing of the whole star feeding machine must be firmly connected, meanwhile, the whole machine should be kept in a horizontal state.

- Check all fasteners to make sure connections well and machines (including motors) are well grounded.

- The whole machine must be kept clean and clean, especially if there is no foreign matter in the shell.

- Check the wiring of the motor so that it has the starting conditions.

- Operational considerations:

- Speed reducer should be according to speed reducer specification, motor steering in the direction indicated by the arrow.

- Attention of the high heating of the motor when starting the power supply, it is necessary to stop and check to avoid affecting the normal operation of the reducer.

- If abnormal vibration is found during operation, stop and exclude.

- Check the heat at the bearing during operation.

- The stuffing gland bolts at both ends should be fastened if leakage of powder occurs on the shaft.

- The bolts should be fastened in time if loose bolts are found in the course of operation.