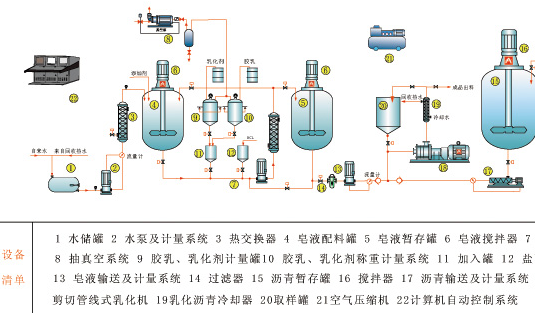

Equipment list: 1. Water storage tanks, 2. water pumps and metering systems, 3. heat exchangers, 4. soap batching tanks, 5. temporary soap storage tanks, 6. soap blenders, 8. vacuum pumping systems, 9. latex, emulsifier metering tanks, 10. latex, emulsifier weighing metering systems,11. adding tanks, 13. Soap conveying and measuring system, 14. filter, 15. bituminous tank, 16. agitator, 17. asphalt conveying and metering system,18. shearing in-line emulsifier, 19. emulsified asphalt cooler, 20. sampling tank, 21. air compressor, 22. computer automatic control system.

Equipment characteristic:

- It adopts the high grade PLC control core, matches the imported frequency converter from Korea, realizes terminal control through the touch screen man-machine interface or the automatic computer operation.

- Super anticorrosive ability, accessories are selected at domestic and international high-end products.

- Bitumen pump with insulated rotor pump or triple screw pump.

- Shanghai fluoride-lined valve is used for pneumatic electromagnetic valve and imported coil is used for regenerator.

- Emulsion pump adopts the famous brand special pump, the emulsifier tank and the latex tank are made of imported stainless steel.

- Three stage high-speed shearing machine, a host equipped with nine pairs of oblique teeth rotor stator shear disc, the fineness of up to 99% of 0.5um-1um (with the same product straight teeth of mainframe can save 10% 15% additive).

- Domestic famous 316L stainless steel disc heat exchanger is adopted in the heat recovery system. It has high efficiency of heat transfer and cooling and never corrodes.

- It can produce high viscosity modified emulsified asphalt and emulsified asphalt with solid content of above 68%.

- Integral convenient hoisting design, quick installation.

- It can be designed to prevent rain roof according to the requirements of different users.

- Dynamic measurement to ensure the quality of modified emulsified asphalt products by stable proportion output of asphalt and emulsion

|

Technical parameter:

|

|

Name

|

Mail power(kw)

|

Produce ability

|

L×W×H(m)

|

|

LQR-5

|

32.3

|

6T/H

|

8.5×2.2×2.6

|

|

LQR-10

|

40

|

10T/H

|

10×2.2×2.7

|

|

LQR-15

|

53.8

|

15T/H

|

12×2.2×2.7

|

|

LQR-20

|

69

|

20T/H

|

13×2.5×3

|

|

LQR-30

|

87

|

30T/H

|

14×3×3.5

|

|

| |